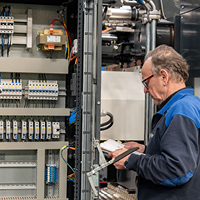

The high-performance

screw, combined with the reinforced screw drive, ensures high output

and consistent melt quality, even with materials with low MFI.

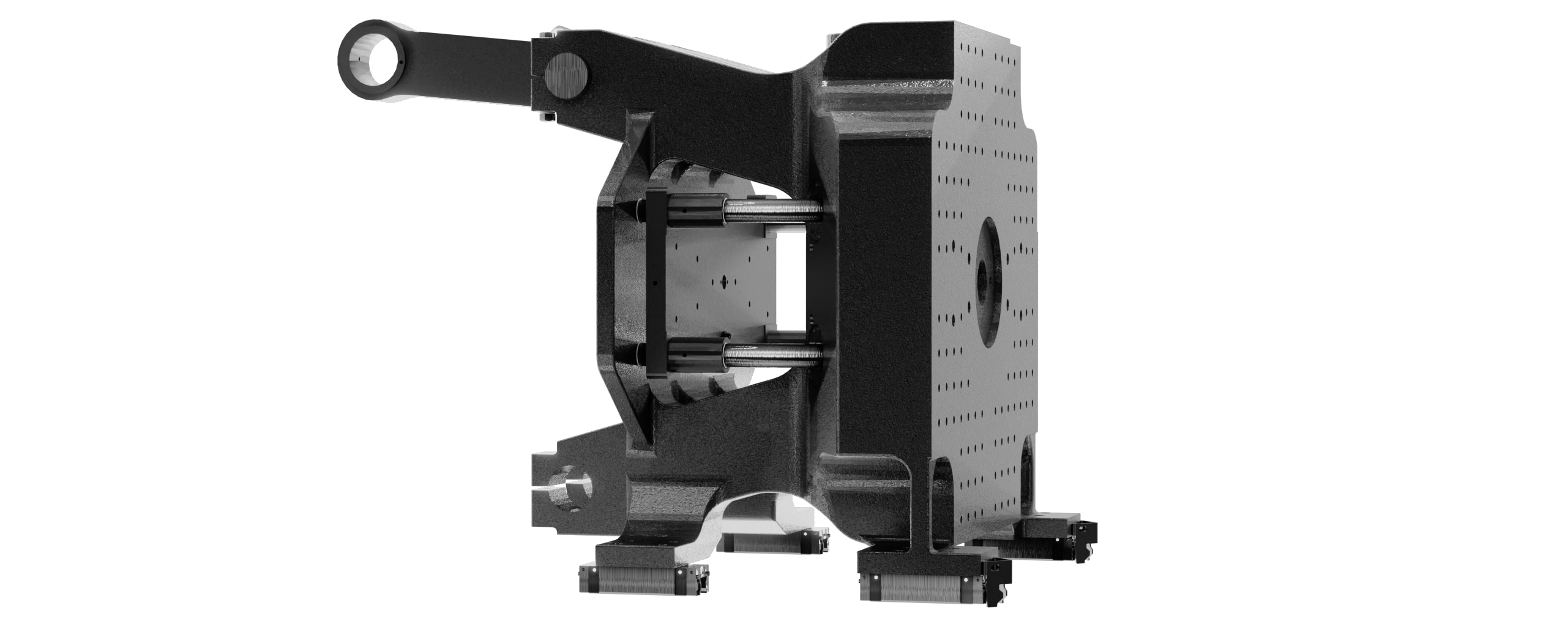

The Stork

Injection Control software guarantees stable shot weight, directly

contributing to uniform product quality – essential for multiple cavities.

A melt

filter with an extra-large surface ensures low pressure drop and prevents

blockages with contaminated recycled streams, increasing process reliability.

Our

machines are also equipped with mould protection, freely programmable core

pullers for demoulding functions or inserts, and a startup program for

stable startup after downtime. The raised drop opening allows for

free-fall removal, ideal for integration with automatic stackers or robot

lines.